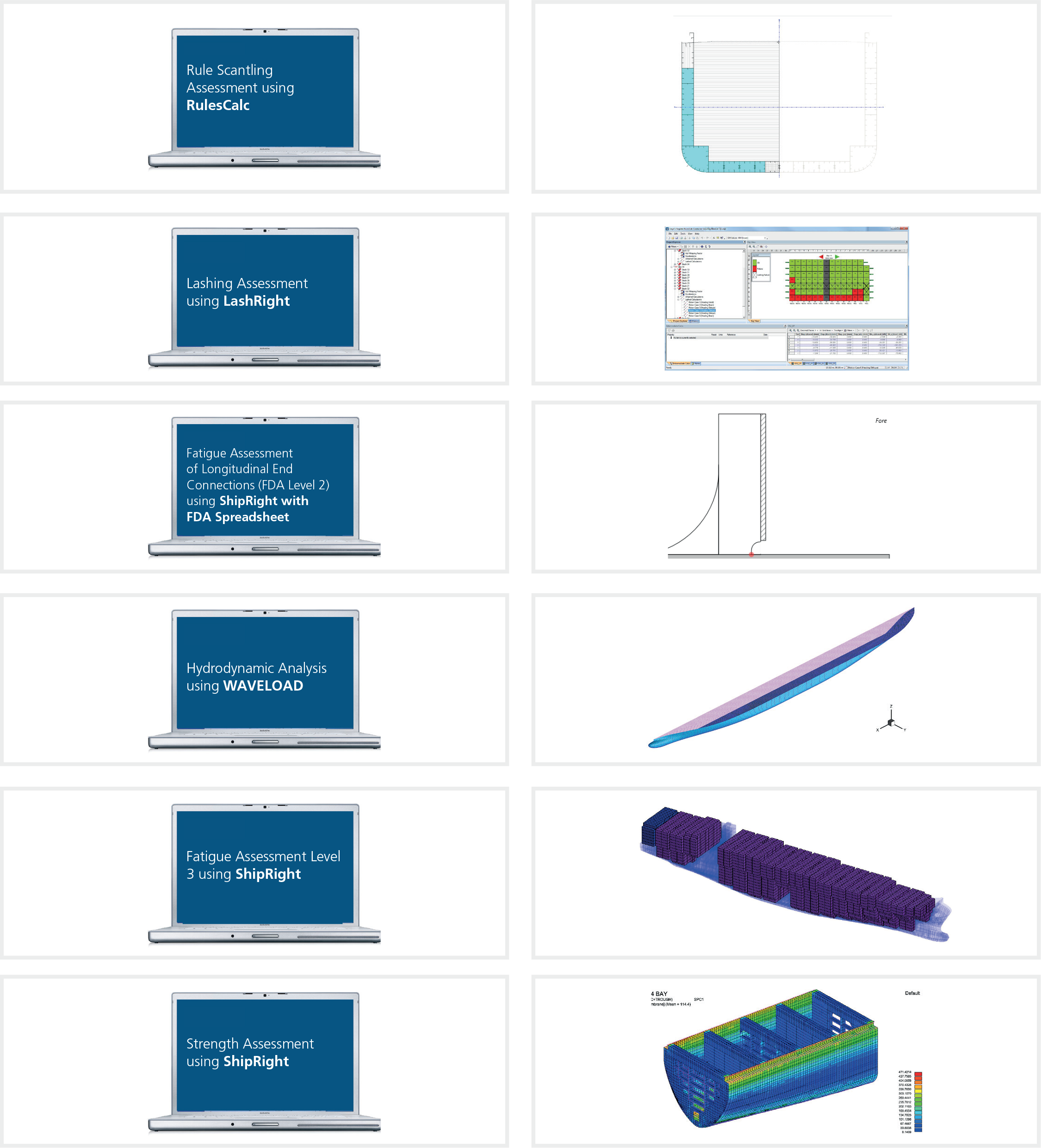

Steps to classification

Rule Scantling Assessment

The traditional strength assessment of a hull is to use beam theory. The hull is assessed as a girder loaded in bending and shear, and each deck, bulkhead and shell as separate boundaries exposed to a pressure differential. Although simplified, it is relatively quick to iterate designs with this assessment and it can provide a good estimate of the final lightship steel weight necessary for structural integrity. The assessment of operational, inspection / maintenance, and flooded loading conditions can be assessed with the RulesCalc software. The Rule scantlings assessment cannot capture the interaction of transverse and longitudinal structures, so a final confirmation is required by finite element analysis. This is carried out in Step 4 and uses the Rule-compliant scantlings determined in RulesCalc as its input. This level of detail significantly reduces the amount of re-work needed when the design is assessed with finite element analysis.

Strength Assessment

In order to confirm that the hull structure will not yield or buckle in-service, a strength assessment is required. This is carried out by finite element analysis using a 3D model. Using a finite element model allows complex geometries and loading distributions to be analysed, which otherwise cannot be represented by beam theory. The pre and post processor for the strength assessment is the ShipRight software, which processes finite element models and results in the NASTRAN format. The assessment can be carried out on both three-hold and full ship length finite element models.

Fatigue Assessment of Longitudinal End Connections

Due to the nature of their construction and cyclic environmental loads in-service, the hulls of ship units are susceptible to cracks forming and propagating. These cracks, if not addressed, could lead to total loss of structural integrity. To help mitigate this, a fatigue assessment is required to be carried out at the design stage to ensure that the likelihood of cracks initiating is at a low level. ShipRight FDA Level 2 employs an advanced spectral fatigue method to assess the fatigue damage of Longitudinal End Connections. For a typical vessel the procedures require over5000 critical fatigue locations to be assessed; ShipRight FDALevel 2 software provides a fast and effective tool to perform this task. It uses a beam theory model of the hull combined with stress concentration factors to represent the level of pressure at the connections. The short-term fatigue damage is determined for each sea state from the trading wave environments.

Hydrodynamic Analysis

In order to assess the strength and fatigue resistance of a hull, it is necessary to know how the vessel responds to waves. The vessel will experience loads, which will cause it to deform and accelerate. These loads and accelerations can be determined by a hydrodynamic analysis using the WAVELOAD software, which is a boundary element potential flow code. The loads and accelerations are determined for individual waves of defined amplitude, frequency and heading relative to the vessel.

Fatigue Assessment Level 3

Due to the nature of their construction and cyclic environmental loads in-service, the hulls of ship units are susceptible to cracks forming and propagating. These cracks, if not addressed, could lead to total loss of structural integrity. To help mitigate this, a fatigue assessment is required to be carried out at the design stage to ensure that the likelihood of cracks initiating is at a low level.

FDA2: The fatigue assessment is done in two stages using the ShipRight software. First, the fatigue resistance of standard longitudinal end connections along the full length of the unit is determined. This uses a beam theory model of the hull combined with stress concentration factors to represent the stress level at the connections.

FDA3: Secondly, a fatigue assessment by finite element analysis is carried out in order to assess details with more complex geometries for example topside module supports and stringer brackets. This assessment can be carried out on both threehold and full ship length finite element models. Both stages use a spectral fatigue approach, calculating fatigue damage for each sea state in the site-specific Metocean data. Wave scatter diagrams can also be processed, for example for the delivery voyage or previous operation as a trading tanker. The contribution of low cycle fatigue from tank loading and offloading can also be included in the fatigue assessment.

Sloshing Assessment

Aquarius is our computational fluid dynamics (CFD)-based software package. It provides an assessment against the Lloyd’s Register ShipRight SDA (Structural Design Assessment) procedures for boundary structures of partially filled tanks and liquid carrying holds.